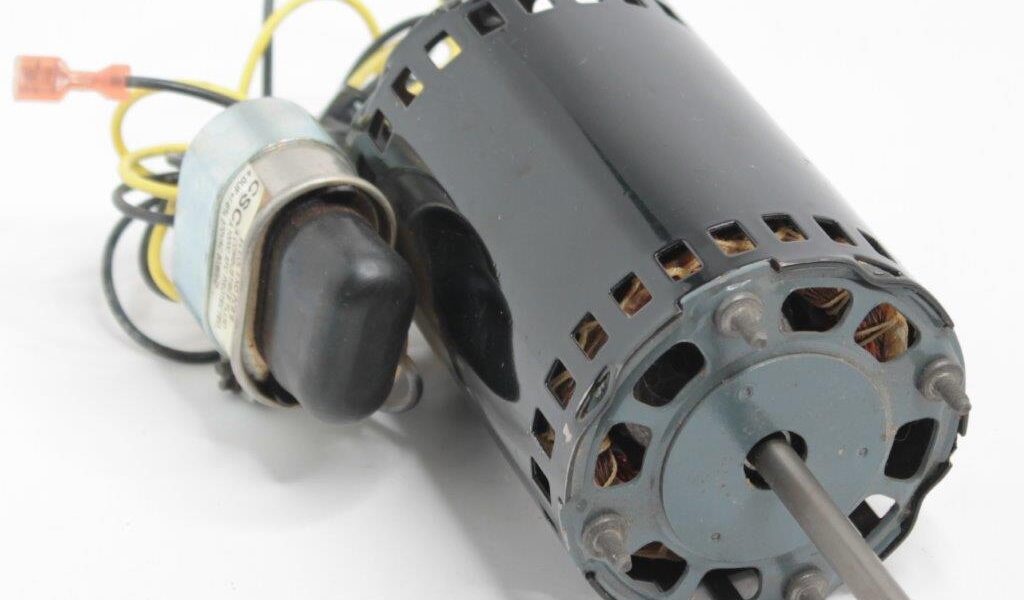

Introduction to Motor Capacitors

Motor capacitors are critical components in single-phase AC motors, serving essential functions that facilitate motor efficiency and operation. These capacitors can be categorized mainly into two types: start capacitors and run capacitors. Understanding the role of each and how they influence motor performance provides a foundational knowledge crucial for anyone involved in electrical or HVAC work.

The Role of Motor Capacitors

- Start Capacitors: These capacitors provide an extra voltage boost or phase shift to the motor windings during startup, increasing the starting torque of the motor. They are momentarily engaged and then taken out of the circuit once the motor reaches a certain speed.

- Run Capacitors: Unlike start capacitors, run capacitors remain in the circuit as long as the motor is running. They improve the motor’s energy efficiency and stability by maintaining a consistent voltage supply and improving the power factor.

How Capacitors Influence Motor Operation

- With a Good Capacitor: A motor equipped with a functional capacitor starts promptly and runs smoothly and efficiently. The capacitor ensures the motor’s current draw is balanced and in phase with its voltage, optimizing performance.

- With a Weak Capacitor: A motor with a weak capacitor struggles with starting and maintaining torque. The phase shift is not adequate, leading to increased power consumption and reduced efficiency. Over time, this can cause motor overheating and premature failure.

- With a Dead Capacitor: A motor with a dead capacitor may not start at all, or if it does, it will run inefficiently with a high risk of overheating. The absence of the capacitor’s phase-shifting ability leaves the motor struggling to maintain its torque.

Start vs. Run Capacitors

While both types of capacitors serve to enhance motor operation, they have distinct characteristics and roles within the motor circuit:

- Start Capacitors: Have higher capacitance values to provide the necessary torque boost during startup. They are designed to be in the circuit for only a short duration and cannot sustain continuous operation without risking damage.

- Run Capacitors: Feature lower capacitance values since they are designed to operate continuously. They provide ongoing phase correction and efficiency improvements during the motor’s operation.

Capacitor’s Operational Necessity

The capacitor is crucial during the start phase for motors that require a starting capacitor. Once the motor reaches its operational speed, the start capacitor is disconnected by a centrifugal switch or electronic relay. For run capacitors, they are needed 100% of the time during the motor’s operation to maintain efficiency and stability.

When to Replace Motor Capacitors

Capacitors should be replaced when they show signs of wear, such as bulging, leakage, or when a motor exhibits starting or running issues that suggest capacitor weakness or failure. Regular maintenance checks can preemptively identify capacitors that are nearing the end of their service life.

Summary of Theoretical Overview

Understanding the theoretical background of motor capacitors illuminates their critical role in motor performance and longevity. Recognizing the symptoms of capacitor failure and the differences between start and run capacitors is essential for diagnosing and addressing motor issues effectively.

Now let’s move to Practical Implementation and Benefits of Capacitors in Motors