Electrical motors are integral to the functionality of a vast array of systems within HVAC and industrial environments. They are pivotal in applications ranging from driving fans and compressors in HVAC units to powering machinery in manufacturing processes. Here’s how these applications manifest in practical settings:

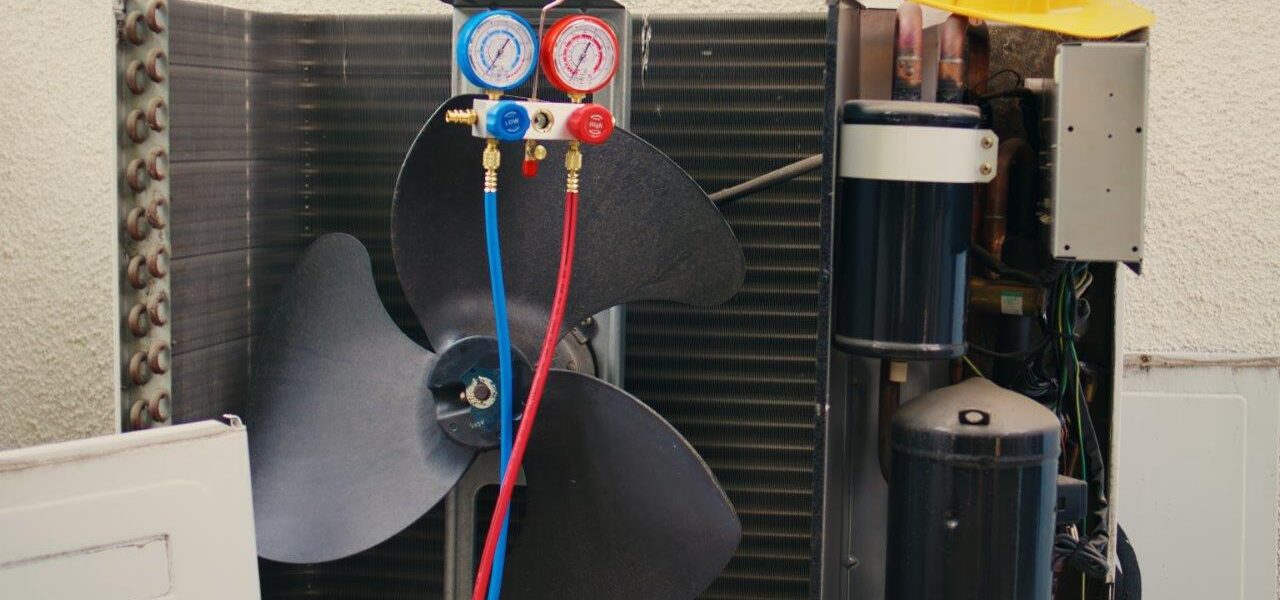

- HVAC Systems: In HVAC units, motors power compressors and fans, crucial for air circulation and temperature control. Efficient motor operation ensures optimal climate control and energy efficiency.

- Industrial Machinery: Motors drive the core mechanisms in industrial equipment, from conveyors to pumps, playing a vital role in operational efficiency and productivity.

Substituting and Matching Motors

When it comes to replacing or upgrading motors, matching the right motor to the application is key. Here are factors to consider:

- Compatibility: Ensure the replacement motor has the correct voltage, horsepower, and RPM to match the application’s requirements.

- Mounting and Frame Size: Match the motor frame type and size to ensure it fits the existing setup without modifications.

- Electrical Specifications: Align the motor’s current rating and phase type with your system’s electrical supply and load requirements.

Signs of Motor Wear and End-of-Life Indicators

Motors exhibit distinct signs as they approach the end of their operational life:

- Overheating: Excessive heat generation can indicate worn bearings or electrical overload.

- Unusual Noises: Grinding or humming noises can signify internal wear or electrical issues.

- Operational Inefficiency: Diminished performance or sporadic operation can signal impending failure.

Prolonging Motor Life

To extend the life of a motor, regular maintenance is crucial:

- Lubrication: Ensure bearings are adequately lubricated to reduce friction.

- Cleaning: Keep motor components clean to prevent overheating and wear.

- Inspections: Regularly inspect and test motor operation to identify and address issues early.

Replacing Capacitors and Identifying Motor Frame Types

Capacitors play a critical role in motor start-up and operation. When replacing, ensure the new capacitor matches the specifications of the original. For motor frames, understanding the specific frame type helps in selecting the right replacement motor, ensuring compatibility and ease of installation.

Conclusion: The Practical Benefits of Motor Maintenance

Effective motor management in HVAC and industrial settings not only ensures operational efficiency but also enhances system reliability and extends equipment lifespan. By understanding the practical aspects of motor usage, from selection and maintenance to troubleshooting and replacement, you can optimize the performance and longevity of these essential components.