What are Motor Brushes?

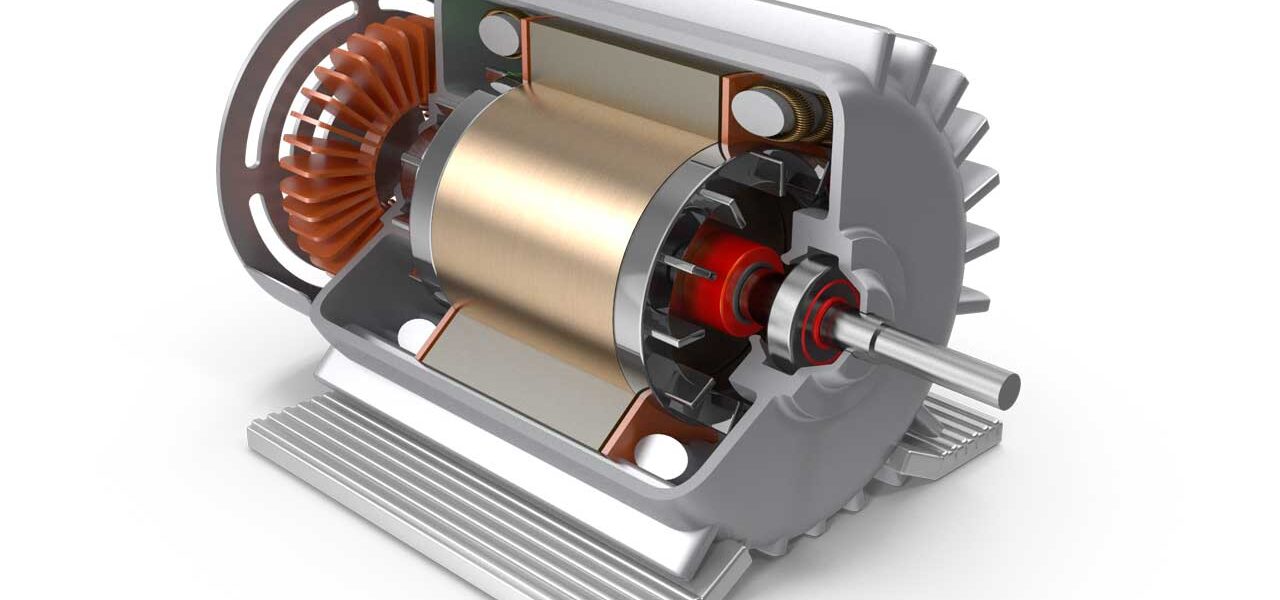

Motor brushes play a crucial role in the operation of many electric motors. They are small blocks of carbon or graphite that conduct electricity between stationary wires and moving parts, specifically within a motor’s rotating shaft. The presence or absence of brushes divides motors into two main categories: brushed and brushless.

Brushed Motors: An Overview

Brushed motors have been the backbone of many electromechanical systems for decades. The brushes inside these motors press against the commutator, transferring electricity to the armature (rotating coils), which creates a magnetic field that drives the motor.

What are Key Features of Brushed Motors:

- Simplicity in design and control

- Lower initial cost

- Easier to repair due to their less complex construction

However, brushed motors have their downsides, including:

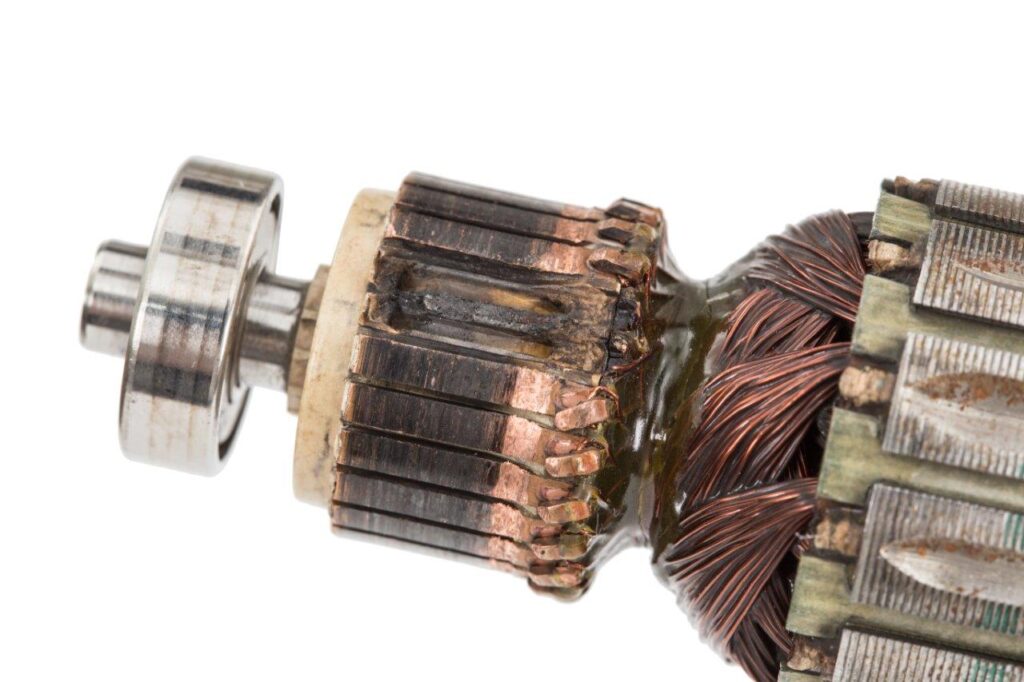

- Wear and tear on brushes leading to maintenance requirements

- Less efficiency due to friction and heat generation

- Lower speed and torque capabilities compared to brushless motors

Brushless Motors: An Overview

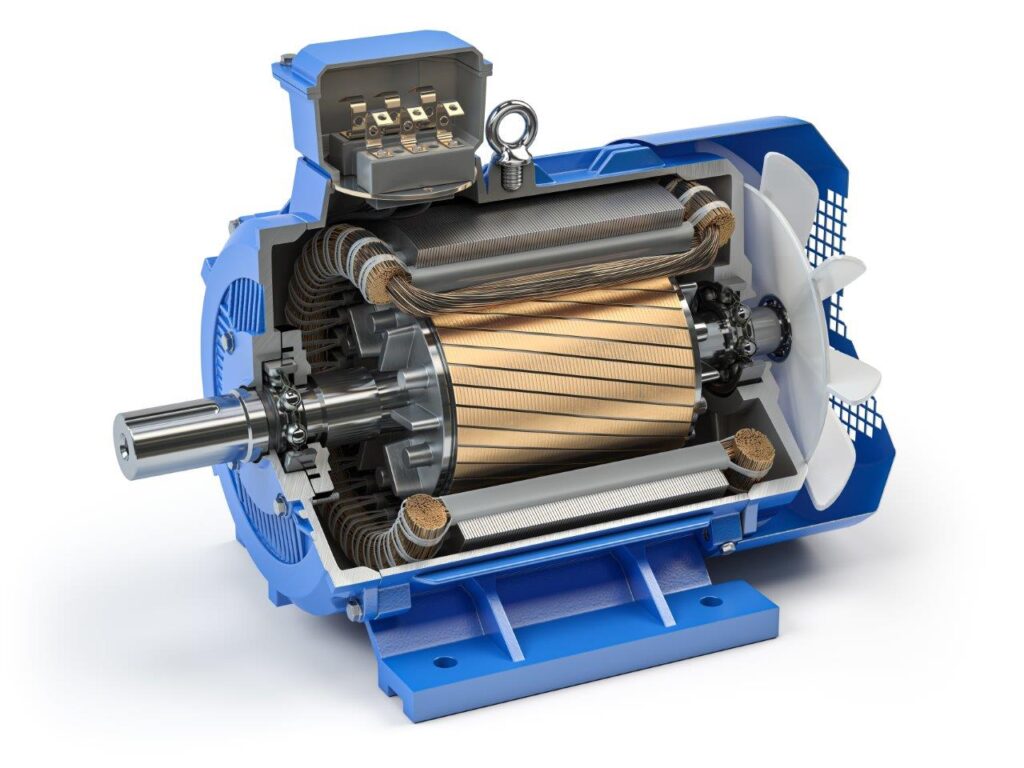

Brushless motors, as the name implies, eliminate the need for brushes. They use an electronic controller to switch the phase to the windings, thus generating the magnetic field that turns the rotor, a more efficient and reliable method.

Key Features of Brushless Motors:

- Higher efficiency and reliability

- Longer lifespan due to the absence of brush wear

- Lower noise and operationally smoother

- Better speed and torque characteristics

Despite their advantages, brushless motors can be more expensive upfront and require a more complex control system.

Comparison of Motor Operation

When comparing brushed and brushless motors, several aspects stand out:

- Productivity: Brushless motors are generally more productive due to their efficiency and speed capabilities.

- Longevity: Without brushes to wear out, brushless motors typically have a longer operational life.

- Noise: Brushless motors are quieter, having fewer mechanical parts involved in the operation.

- Maintenance: Brushed motors require more maintenance to replace worn brushes and clean the commutator.

Examples from Life

In everyday applications:

- Brushed motors are often found in simple household appliances and tools, like hand mixers and drills.

- Brushless motors are commonly used in high-end appliances, computer fans, and in the automotive industry, particularly for electric vehicle powertrains.

Running Differences and Similarities

- Operation:

Brushed motors might experience a drop in efficiency over time as brushes wear down, whereas brushless motors maintain consistent performance. - Control: Brushless motors require electronic control, which can precisely manage speed and torque. Brushed motors are controlled by varying the voltage or resistance in the circuit.

Benefits of Brushed and Brushless Motors

Practical Applications of Brushed Motors

Brushed motors, given their simplicity and cost-effectiveness, find utility in various everyday applications. Here’s where they shine:

- Automotive: Used in car starters and windshield wipers, where robustness and cost-efficiency are paramount.

- Household Appliances: Employed in vacuum cleaners, food processors, and drills, offering a cost-effective solution for intermittent usage.

- Industrial Tools: Ideal for portable power tools and other devices where the motor’s simplicity and ease of replacement are beneficial.

Despite their widespread use, the maintenance aspect of brushed motors cannot be overlooked. Regular checks are necessary to replace worn brushes and maintain performance, especially in industrial settings where downtime can be costly.

Practical Applications of Brushless Motors

Brushless motors are preferred in applications where efficiency, longevity, and low maintenance are crucial:

- Drones and Model Aircraft: These motors provide the necessary power and reliability for extended flight times and precise control.

- Electric Vehicles (EVs): The efficiency and durability of brushless motors are key advantages in EV powertrains, contributing to the vehicle’s overall performance and range.

- Computer Hardware: Brushless motors power cooling fans in computers, ensuring quiet operation and longevity crucial for maintaining system performance.

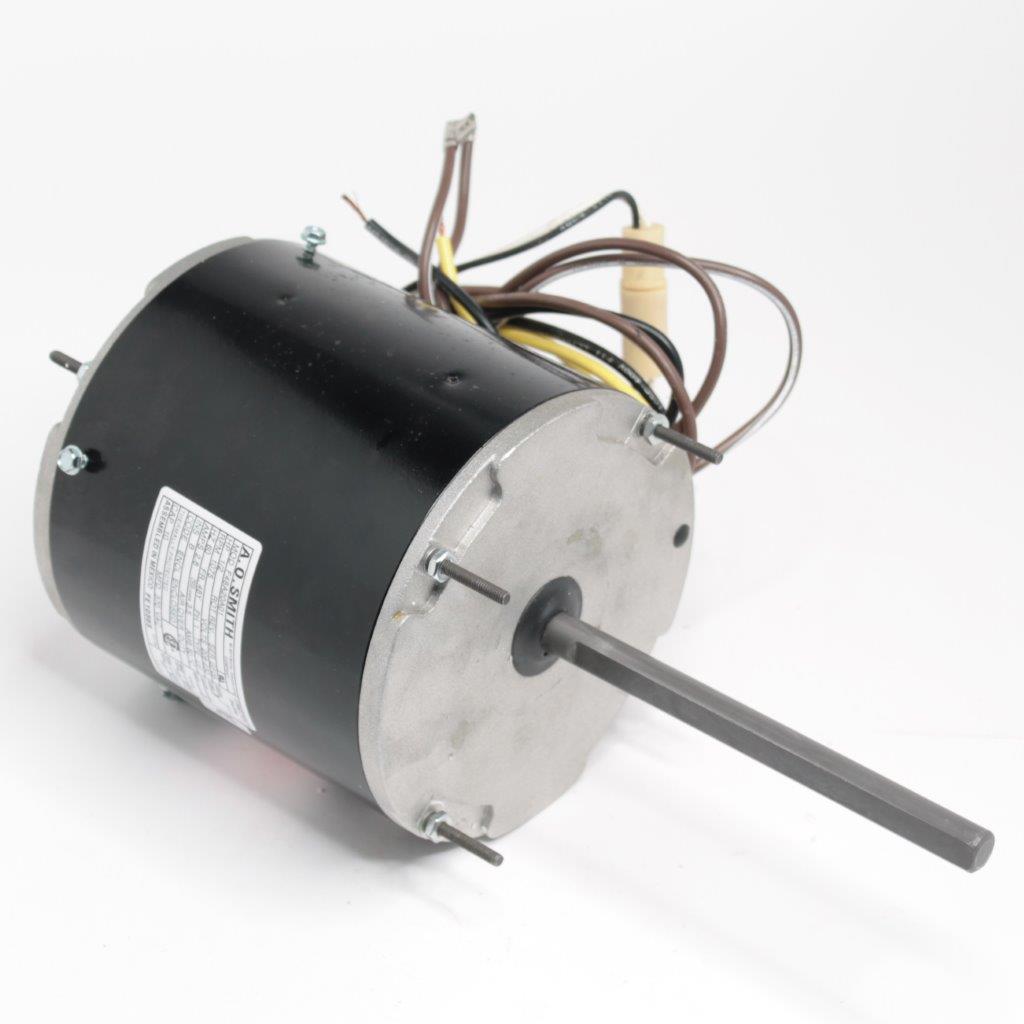

- HVAC Systems: High-end HVAC systems utilize brushless motors for their energy efficiency and better control over air movement.

- Industrial Automation: Brushless motors are favored in automated systems and robotics for their precise control and long service life

The initial cost of brushless motors is offset by their reduced maintenance needs and longer lifespan, providing value in applications where reliability is key.

Benefits of Each Motor Type

- Brushed Motor Benefits:

- Cost: Generally less expensive to produce and purchase.

- Repairability: Easier to service due to their simpler design.

- Control: Simpler control mechanisms can be an advantage in rudimentary applications.

- Brushless Motor Benefits:

- Efficiency: More energy-efficient, converting a higher percentage of electrical energy into mechanical energy.

- Longevity: Fewer moving parts reduce mechanical wear, extending the motor’s lifespan.

- Performance: Higher speed and torque capabilities suit a wide range of advanced applications.

Matching and Substituting Motors

When substituting or selecting a motor for a specific application, consider the following:

- Compatibility: Ensure the replacement motor has the same voltage, current, and physical dimensions as the original.

- Application Requirements: Evaluate the need for speed, torque, and control. Brushless motors are better for applications requiring precise speed and torque control.

- Environmental Factors: In environments where maintenance is challenging or where motor noise is a concern, brushless motors are advantageous.

Signs of Motor End of Life and Prolongation Strategies

- End-of-Life Signs: For brushed motors, frequent sparking, reduced performance, or excessive noise can indicate wear. For brushless motors, performance drop or electronic controller issues might signal end-of-life.

- Prolongation Strategies: Regular maintenance, including brush replacement for brushed motors and firmware updates for brushless motor controllers, can extend motor life. Ensuring proper load matching and avoiding overheating also contribute to longevity.

- Noise: Increased noise can indicate wear or alignment issues, especially in brushed motors where brush or bearing wear is common.

- Heat: Excessive heat generation may signal overloading or friction within the motor, necessitating a check-up or replacement.

- Reduced Performance: Sluggish operation or failure to start can be tell-tale signs that a motor is nearing its end-of-life.

- Regular Inspection: For brushed motors, regular inspection and replacement of worn brushes can prolong life. For brushless motors, monitoring the electronic controller and bearings is key.

Harnessing Motor Technologies Effectively

Understanding the practical applications, benefits, and maintenance strategies for brushed and brushless motors empowers professionals to choose and manage these essential components effectively. Whether in consumer electronics, automotive applications, or industrial machinery, selecting the right motor type can significantly impact performance, efficiency, and operational costs.