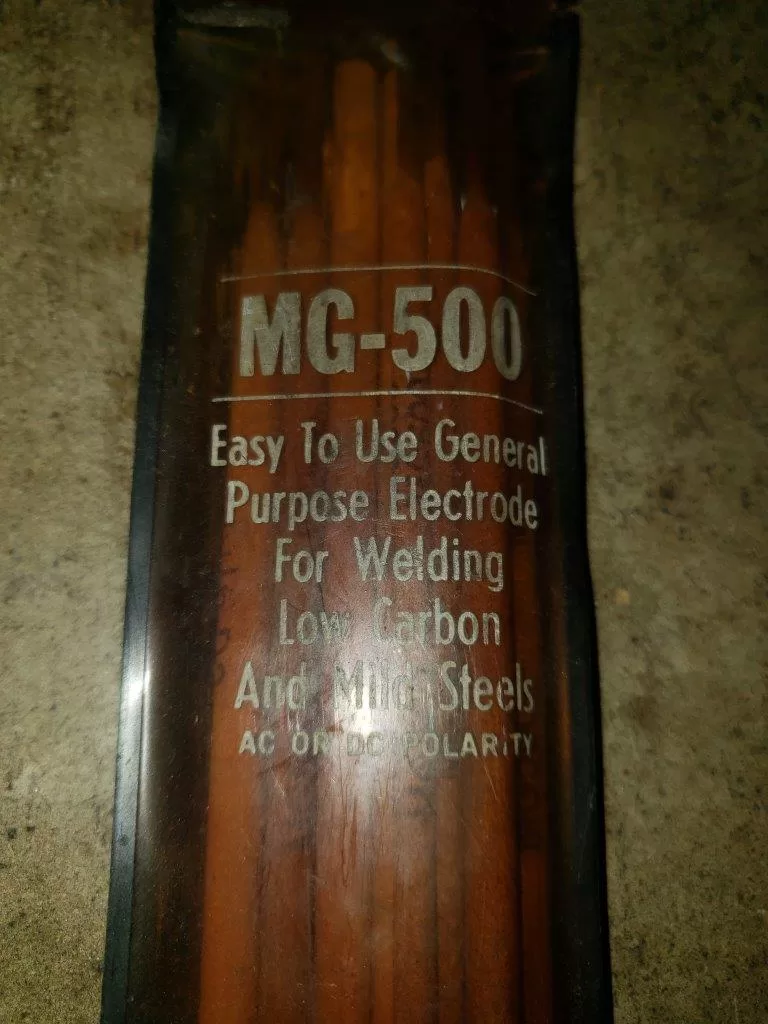

Welding rods MG 500 Mild Steel Alloy 1/8″ and 3/32 inch rod electrode set

Original price was: $19.99.$12.50Current price is: $12.50.

We might not have it

Easiest-to-use, all position electrode for mild steel from MG Welding

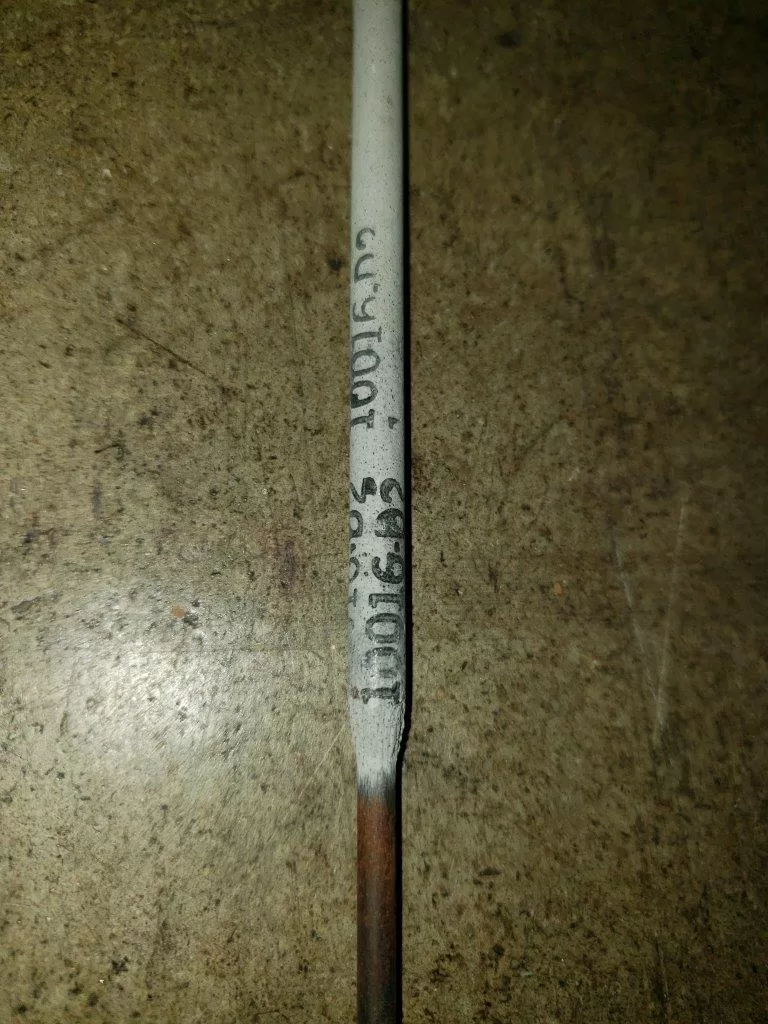

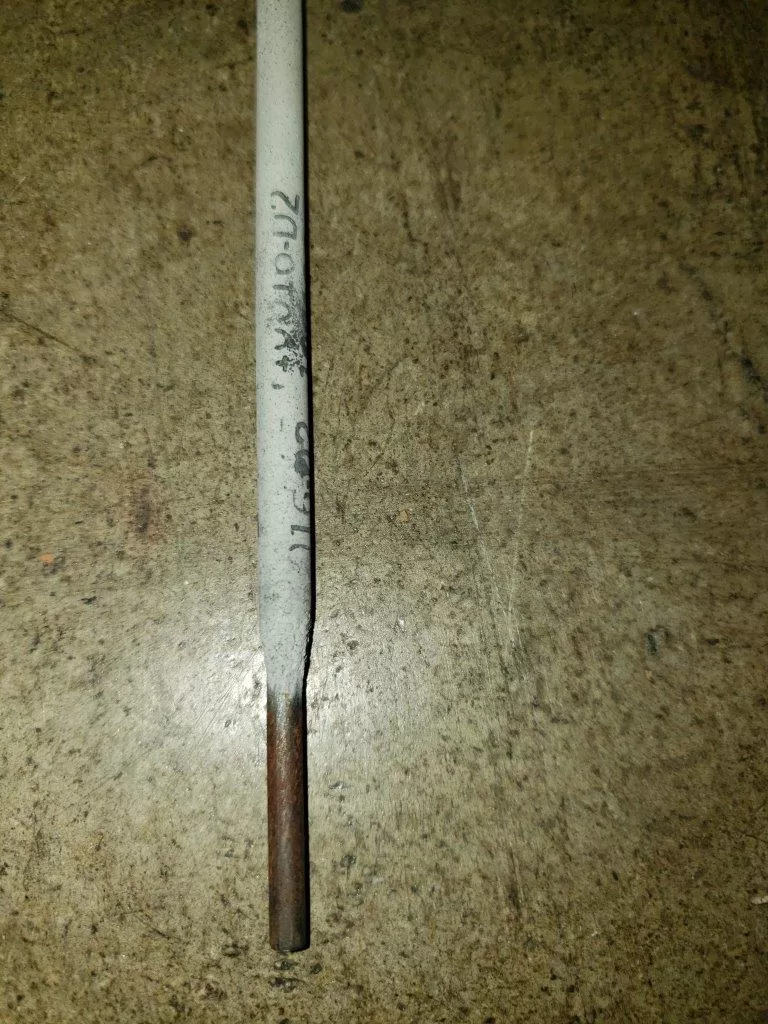

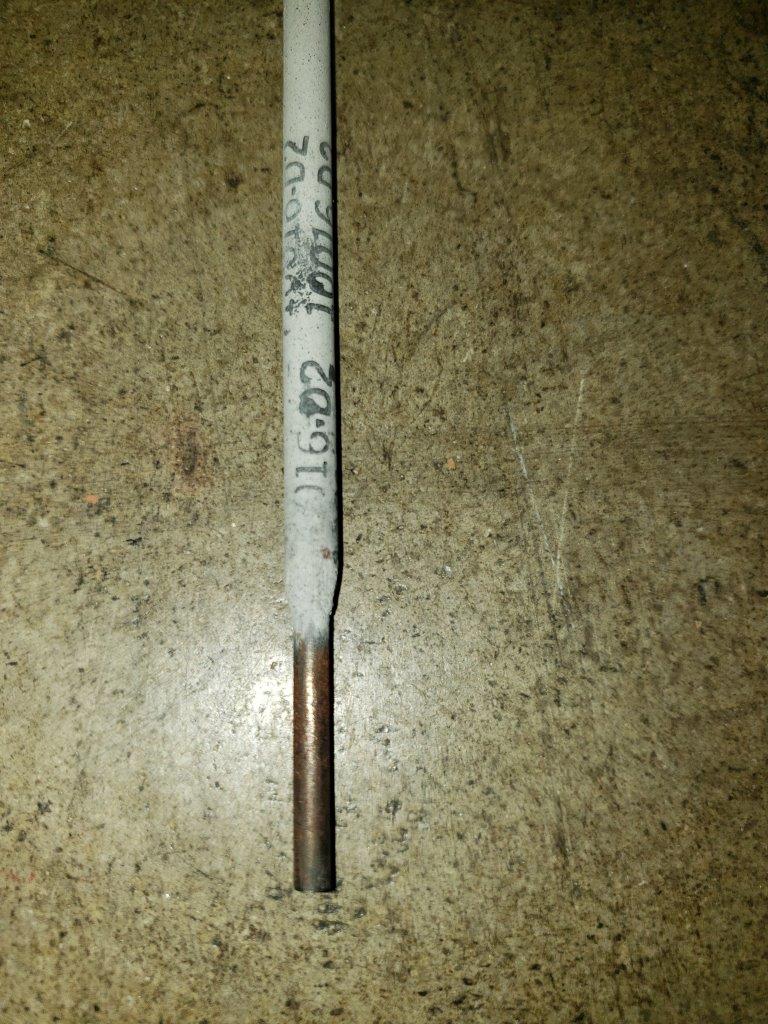

The pouch contains 4 rods 3/32 inch and 6 rods 1/8″

Very low amperage requirement on AC and DC.

Ideal for out of position welding.

Outstanding restrike characteristics, minimal spatter, and self-releasing slag.

Great for fabrication of thin, medium, heavy, and dissimilar sizes and grades of steel.

For uses such as: sheets & plates, angle iron, pipes, build-up of worn surfaces, general construction and repair applications.

This electrode has been designed to operate on almost any AC or DC welding machine even when the open circuit voltage is very low. The special coating protects the weld deposit from adverse conditions normally encountered in maintenance repair welding. Low amperage requirement controls distortion when welding thin sheet metal; spatter is kept to a minimum. Ideal for field repair work and out-of-position welding.

APPLICATIONS:

Fabrication of thin, medium, heavy and dissimilar gauge mild steels. Sheets, plates, angle iron, beams, pipes and machine parts can be welded in all positions. Also used for filling holes and build-up of over-machined and worn surfaces. Commonly used on applications requiring short, intermittent and spot welds because of the outstanding restarting characteristics.

Diameter | Amperage

3/32” (2.4mm) | 35-80

1/8” (3.2mm) | 65-125

TECHNICAL DATA:

Typical Tensile Strength Up to 80,000 psi (552 N/mm2)

Typical Yield Strength Up to 68,000 psi (469 N/mm2)

Elongation Approx. 24%

Current AC or DC either polarity

PROCEDURE:

Remove as much foreign material as practical from the weld area. DC reverse polarity (electrode +) produces deep penetration; DC straight polarity (electrode -) will have limited penetration and a flatter bead. AC prevents arc blow. A medium arc length should be maintained with either stringer or weave beads. Slag is easily removed with a light chipping hammer.

Welding rods labeled as MG 500 typically belong to the category of low hydrogen electrodes used in manual metal arc welding (MMA) or shielded metal arc welding (SMAW). The designation “MG” often refers to the electrode’s characteristics or specific properties, and “500” might denote a particular classification or code associated with the rod.

These rods are often designed for welding high-strength steels, including certain grades of carbon and low-alloy steels. They are known for their ability to produce welds with low hydrogen content, which is crucial in preventing hydrogen-induced cracking in high-strength steel applications.

| Weight | 5 lbs |

|---|---|

| Dimensions | 14 × 6 × 2 in |

You must be logged in to post a review.

Reviews

There are no reviews yet.